The automotive industry, and more generally the mobility industry, is constantly evolving and must meet increasingly demanding constraints. It is in this context that a wide range of adhesives find their place.

This article will explore the various applications of pressure-sensitive adhesive tapes in the automotive and transportation sectors, and why they are a preferred fastening solution.

Automotive adhesive tapes

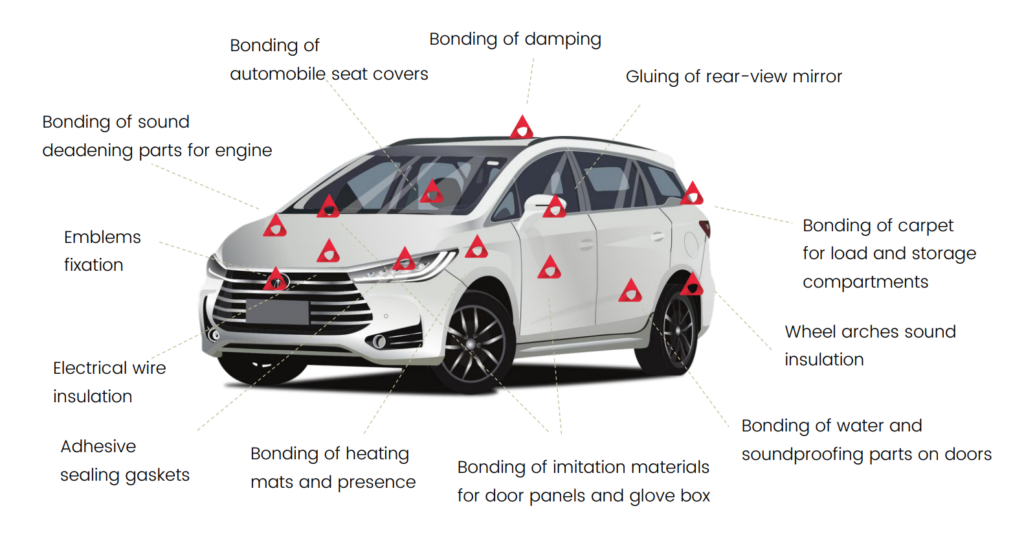

Bonding, assembly, protection, soundproofing, sealing… even if we can’t see them, adhesive tapes have multiple functions in all vehicles.

Each function requires a specific solution. The choice of adhesive (nature and quantity), backing, and liner will be crucial to meet the application’s needs.

Here are a few examples of applications ADESIA addresses for its automotive clients:

- Bonding of PU or PE foam to die-cut leather or textile flanks, intended for the manufacture of seat covers or headrests

- Fixing of rear-view mirror glasses

- Fixing of decorative elements

- Upholstery

In less visible but no less critical areas, some adhesives provide soundproofing, thermal insulation, or vibration dampening characteristics. These adhesives are used in:

- The interior

- Wheel arches

- The bodywork

- Engine block

Adhesive tapes for the mobility sector

Transportation vehicles (buses, trucks, trains, and other utility vehicles) also require the use of technical adhesive tapes.

Constantly subjected to harsh environments, heavy-duty and public transportation vehicles require great durability.

In the case of public transportation, adhesives are particularly used for the fixation of floor coverings, which are subjected to intensive use (high traffic), temperature variations, humidity, UV rays, and chemical compounds (plasticizers).

Of course, they are also used in the manufacturing of the structure, engines, trim elements, insulation system, and even for temporary repairs!

Why adhesive tapes are an excellent solution for automobile and mobility sector ?

Adhesives offer numerous advantages in automotive applications.

Composed of at least a backing material and an adhesive film, adhesives offer great lightness, which translates into a reduction in the overall weight of the vehicle.

Presented in roll form, adhesives can be more or less wide or long depending on the needs. During application, the adhesive surface is distributed uniformly, thus absorbing stresses in a coherent manner. This improves the overall strength and durability of the fastening system.

Adhesives designed for the automotive sector can be used in many locations of a vehicle, even the most demanding. This unique quality of adhesive solutions allows for more complex structures or shapes during design.

In accordance with the expectations of this sector, our automotive-specific adhesives are free of hazardous substances, low in VOC (volatile organic compound) emissions and low fogging.

Technical adhesives in the automotive industry are long-term viable products due to their performance and the gains generated at the production level.

Find our automotive adhesives here.