Since 1975, our core business is adhesive coating

Our manufacturing processes

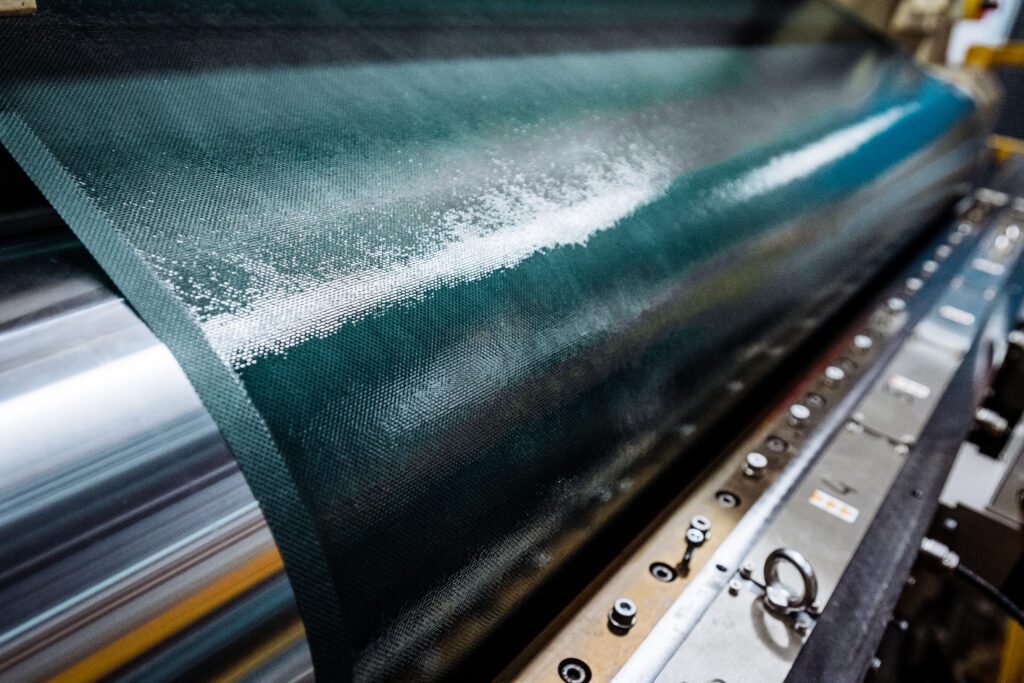

Coating

Adhesive coating requires great skill and constant rigour. It involves coating a few grams of adhesive onto a non-stick liner, precisely and evenly, then drying it to produce a ready-to-use adhesive tape. Our coating lines enable us to achieve a high level of flexibility and meet a wide range of requirements. We can coat materials up to 2 300 mm wide to obtain a coated width of up to 2220 mm. This diversity of coating machines allows us to coat from 20 to 500 g of adhesive per quare meter, depending on the requirements.

Custom coating

The materials we coat can be supplied by our customers, when they entrust us with the adhesive coating, and on condition that the material can pass through the oven of the coating machine.

Lamination, cutting and processing

Once the glue film has been manufactured, other equally technical and specific processing stages follow.

Adhesives

To meet a wide range of applications and specific requirements, we have a varied range of adhesives.

Our pure or modified acrylic water-based formulas offer good levels of adhesion and are versatile. Environmentally friendly, they are ideal in circumstances where VOC emissions need to be as low as possible. Emulsion adhesives are competitive.

For the most demanding applications, we also have pure or modified acrylic solvent-based adhesives. These glues have a very high level of adhesion and can withstand a wide range of external stresses.

Finally, synthetic hotmelt adhesives have unequalled adhesive power. More susceptible to ageing, these hot-melt adhesives also have very high tack.

Our adhesives catalogue also includes speciality adhesive masses such as biocompatible, repositionable or removable, suitable for food contact, flame retardant, etc.

Depending on your needs, our formulation engineers can add a function to the adhesive mass using a colourant, biocide, tackifier or catalyst. In some cases, you can also supply us with your own glue so that we can custom-coat your material.

Liners

The choice of liner plays an important role in the protection, processing, application and handling of the adhesive. Whether it is a glassine paper, a polyester or polypropylene film, thin or thicker, in a particular colour, rigid, hand-tearable, with an overhang to create a finger-lift, allowing kiss cutting or as economical as possible… Our teams will guide you towards the solution best suited to your needs! Where possible, we also offer adhesives without liner, for environmental or processing reasons.

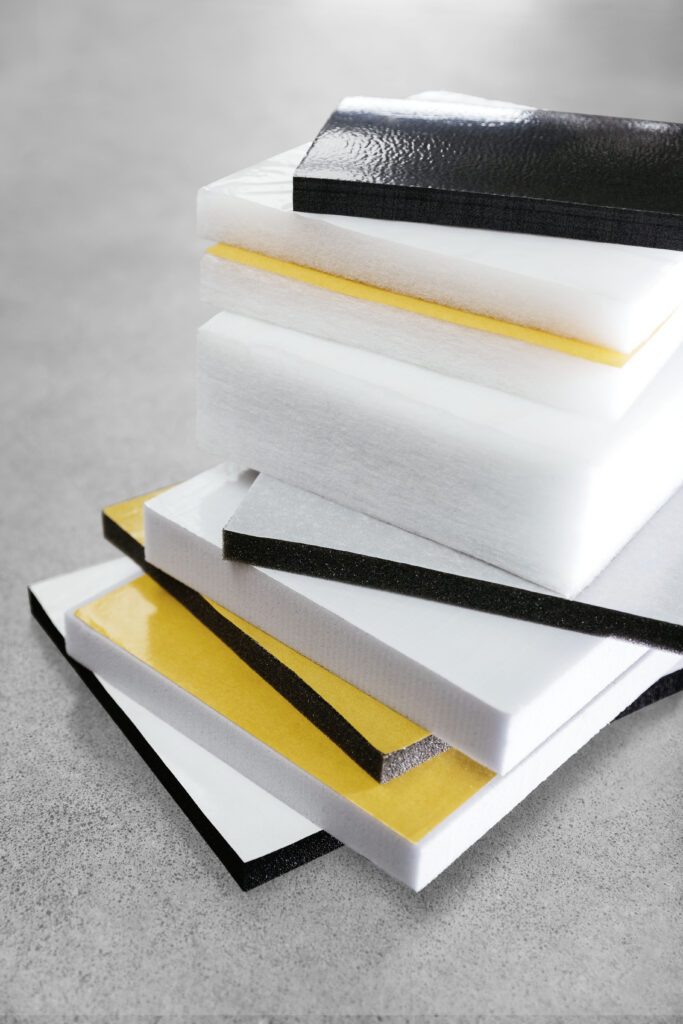

Carriers

Substrates also play a very specific role in the construction of an adhesive tape. Conformability, filling, flexibility, rigidity, watertightness, dimensional stability, on-line detectability… in addition to the adhesive function, the ADESIA teams can advise you on the functionality of the backing. Double-sided or single-sided non-woven, polyester, PVC, foam, mesh, our range of substrates offers you a wide range of possibilities to suit your application.

We offer technical pressure-sensitive adhesive tapes, known as PSA tapes. Depending on your needs, we are able to provide you with transfer, transfer with scrim, double-sided and single-sided tapes. Because every need is unique, and because innovation is one of the pillars of our development, we are always on the lookout for new and innovative products. Here are some of our specialities: adhesives with spaces without glue, hybrid double-sided, adhesives with two liners, reinforced scrim transfers.