Our range of laminating, rewinding and cutting machines enables us to offer our customers adhesive tapes in the dimensions of their choice: width and length.

Our services

After coating, we can offer various possible transformation of the tape :

- Lamination and bonding

- Width and length adjustment

- Packaging et personnalisation

Laminating and complexing

On average, we stock almost 300 000 m² of flexible customer materials on rolls to make them self-adhesive. With very few exceptions, these materials cannot be processed in the ovens of coating machines. In these cases, we laminate an adhesive film onto the material, using a lamination machine.

Adhesive film can be laminated to 2 sides of the same material to make it double-sided adhesive.

Our expertise in materials also enables us to assemble two materials using adhesive: this is called joining.

Entrust us with your project and boost the potential of your materials by making them self-adhesive!

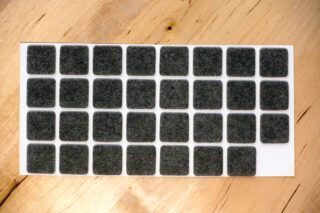

Winding and cutting

Our rewinding and slitting machines allow us to offer adhesive tapes in the dimensions of your choice: in width and length.

Depending on the product, we can cut tapes from 6mm width upwards.

For large production runs, we have two automatic cutting tools.

An industry standard, we work mainly on 3-inch (76 mm) cores, plastics or cardboard, and in a range of thicknesses to suit your needs.

Our methods teams take care to offer optimum presentation of your reels, depending on whether you are working with adapted equipment or whether your staff handle the rolls by hand.

Customization

Printed core,liner or carrier, customized labels and cardboard box: we offer our customers several levels of personalization to enhance their brand.

We can also adapt the packaging and presentation of your tapes to suit your needs. Are you a distributor with specific packaging requirements? Are you looking for a ready-to-sell product, on the shelf, in individual shrink-wrapping? Our teams can offer you a solution tailored to your market.